Electromagnetic interference: Cheap purchase, vehicle at risk

published on 23. September 2025

Electromagnetic interference, or EMI for short, occurs wherever electrical consumers are involved. Vehicle lighting is also affected: headlights can cause interference, but they can also fall victim to external influences themselves. Anyone who thinks this is only a theoretical problem is mistaken. In everyday life, radio signals from smartphones or radios are enough to throw inadequately tested lights out of sync.

Air or cable – how EMI works

Electromagnetic interference can occur in two ways: through the air, when devices emit interference signals or are affected by radio fields, or through cables, when voltage peaks and pulses are transmitted via the vehicle electrical system.

A good light must be able to do both: it must not cause any unacceptable interference itself and must also be resistant to external signals.

In a broader context, this is referred to as EMC, or electromagnetic compatibility. This describes the ability of all electrical devices to work together without interference. EMI is the specific interference factor within this framework.

For readers in a hurry

- EMI (electromagnetic interference) is invisible interference that can affect electronics and lighting.

- It can be transmitted either through the air (radio waves) or through cables (vehicle electrical system).

- Inadequately tested lights can cause interference or be affected by interference themselves.

- Cheap products can not only fail themselves, they can also interfere with or damage other electronics, leading to long downtimes.

- Our products are consistently tested according to international standards. This makes them reliable, durable, and safe.

Why quality matters

Mastering these factors is crucial, especially in vehicles where more and more electronics are working together. Even a single component that has not been tested in accordance with standards can lead to the failure of entire systems.

Cheap products often manage to impress at first glance with their price. But what about after months or years of use? Without consistent testing according to standards such as ECE R10, EN 12895 or SAE J1455, compliance with EMC guidelines remains a matter of luck. An interference pulse from the starter motor or a voltage spike when a coil is switched off can affect not only the light itself, but also cause permanent damage to other control units and electronic components.

The result is not only defective lights, but also tedious troubleshooting, unexpected downtime, and unnecessary costs during operation.

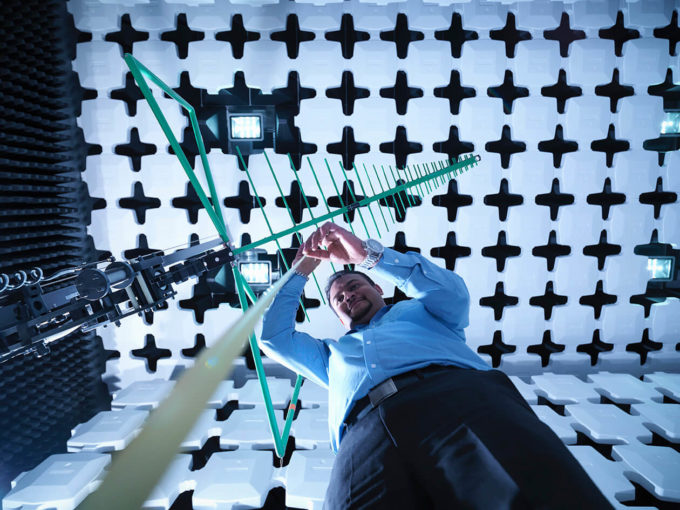

Our answer: Test instead of risk

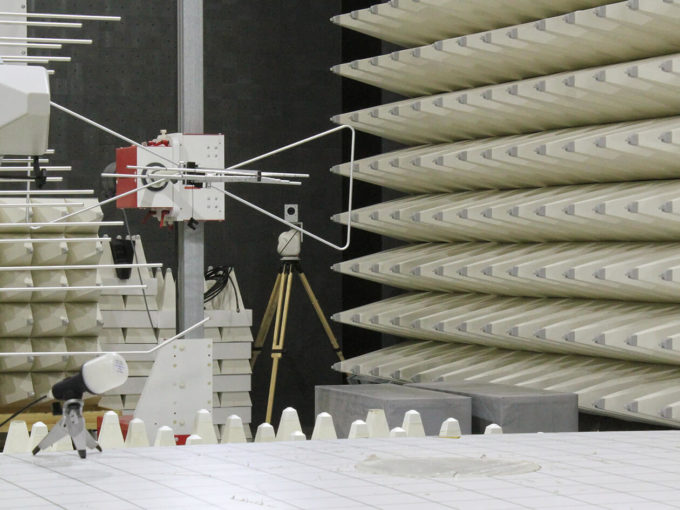

We rely on luminaires that have not only been developed, but also extensively tested, both in the laboratory and under real-life conditions. Each series undergoes testing for burst transients, load dump, and electrostatic discharge. This is a complex process that costs time and money. But it ensures that our products do not fail in the field when it matters most.

And this is precisely where quality differs from cheap goods: with us, protection against electromagnetic interference is not left to chance, but is verifiable. Because in the end, it’s not the euros saved on the purchase that count, but the costs of failure during operation.

How to recognize invisible quality

EMI is invisible. The quality of our products is not. It is evident in interference-free communication, in systems that work together reliably, and in lights that still function even after years of use. That’s why all our products are extensively tested.

We may not be the cheapest on the market. But we can guarantee that our products deliver what they promise. Those who focus on quality don’t save on purchasing, but on operation, through fewer failures, less downtime, and less hassle.

Conclusion

Electromagnetic compatibility is not a “nice to have,” but a must when safety and reliability are paramount. Cutting corners here is a false economy. Our lights undergo extensive testing in accordance with international standards, delivering exactly what counts in use: safety, visibility, and confidence.

FAQ – Electromagnetic Interference (EMI)

What does EMI mean in relation to vehicle lights?

EMI stands for electromagnetic interference. This refers to disturbances that electronic devices can emit or receive, such as radio waves or voltage spikes in the vehicle electrical system.

Why is EMI a problem for LED headlights?

LED lights contain sensitive electronics. Without protection against EMI, flickering, failures, or interference with other systems in the vehicle can occur.

How can EMI be avoided?

Only through comprehensive development and rigorous testing. Standards such as ECE R10, SAE J1455 or EN 12895 ensure that lights do not cause any unacceptable interference and remain insensitive to external influences.

How can I recognize tested quality?

Certifications according to international standards and transparent communication of test procedures are reliable indicators. Products that are “only cheap” usually do not undergo these tests.

tagged with Glossary, Safety, Technology