With Click Bond you secure components safely and lastingly

Need to fix something securely and stably, but can’t weld or drill into the surface? Simply glue it! Click Bond’s fastening system is at your assistance.

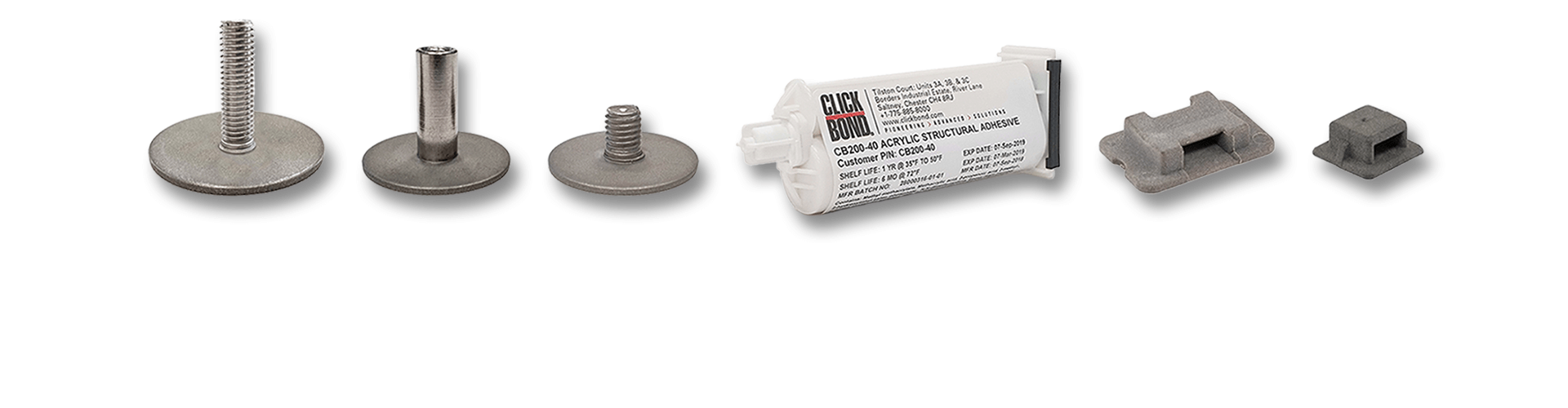

Adhered brackets provide you full flexibility, without interfering with the structural integrity of load-bearing parts! The options are extensive. Select from a wide range of studs, threaded studs, eyelets, and additional components.

Advantages thanks to bonding

- Attachment to highly-stressed, fatigue-sensitive or pressure-subjected components is possible.

- Eliminates costs for drilling and the associated errors in system installation.

- No galvanic corrosion, no crack-initiating holes in stressed parts.

- Special mounting apparatus (included in the supply) ensure optimal adhesion and assembly consistency.

- Baseplates in metal, thermosetting or thermoplastic materials available.

- Metric thread sizes

Quick, easy secure – the way Click Bond mounting works

Each Click Bond holder always has a specially designed mounting apparatus. This not only ensures an easily achieved and yet precise positioning of the holder but also guarantees correct adhesion.

This mounting apparatus applies a precisely defined, continuous pressure to the adhesive joint during the adhesive’s curing, thus ensuring a high-strength fixing of the holder. The outcome: consistently optimal results with every installation.

1. Preparing the mounting surface

The surface is prepared for bounding using proven and simple methods (see instructions enclosed with the holder).

2. Applying the adhesive

Mix the adhesive (according to the instructions) and apply it to the adhesive surface of the holder.

3. Position and press

Positionthe Click Bond holder using the mounting device and activate the contact pressure with a “click”!

〉〉 Already loadable after a short time

The special structural adhesive enables our holders to be securely attached to a wide range of metals, thermoplastics and composite materials. These are usually already 80 percent loadable one hour after application.

Perfect dispensing, no mess – the smart adhesive solution

The Click Bond Syringe gives you full control over your mounting tasks. This combination of a 10ml adhesive and a mixing tip allows you to apply exactly the amount of adhesive you need – with no waste and no mess. Ideal for 5-6 applications, allowing you to work flexibly and efficiently.

Precise dispensing and easy handling make application a breeze. Whether you’re working in production, in the field or on repairs, the Click Bond Syringe ensures a clean and effortless bond that adapts perfectly to your needs. Rely on fast, secure and problem-free mounting – without any unnecessary adhesive residue.

See the Syringe

Ideal for Click Bond – Model 710!

Delivers light where you need it – without dazzling! Model 710 is the perfect spotlight for forklifts.

2 light patterns. Model 710 fulfils two needs in one work light. It acts as a driving light for secure traffic in the warehouse, without dazzling the oncoming traffic. And it can illuminate a rack up to the topmost shelf if needed. Thus, a full 160° vertically can be lit. But naturally, only when necessary.

Mounting directly on the lift mast. With Click Bond, this spotlight can be safely affixed directly on the lift mast, without compromising the carrying structure. Thereby, it operates optimally and can project its full strength.

See Model 710Click Bond Highlights:

A perfect fit for your needs

The range of different holders is huge. Our selection from this range represents only a small part of the entire range, which is designed to optimally fulfil specific requirements in the area of fastening solutions. If you need a bracket that you cannot find in our selection, please do not hesitate to contact us!

Interview with the expert

Bonding expert Sascha Preiss from VTR answered our questions about ClickBond. He talks about the necessary preparations, the variety of applications and the durability of bonded joints. And also about how to remove a bond that is no longer required.

Watch now!

Do you have any questions about our Click Bond products? We’re there to answer them!

Are you looking for the right Click Bond solution? Our experts are happy to help you find the ideal product for your requirements. Then simply call us.

Phone

+49 40 303300-0

Or use our contact form.

CONTACT